High-precision Accelerometer test system

FEATURES

1. Overview

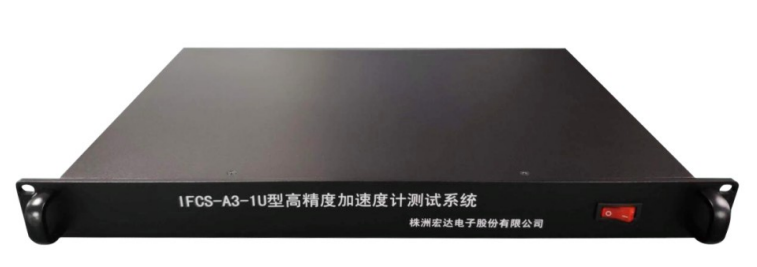

The three-channel high-precision Accelerometer test system will use high-precision I/F conversion circuits combined with high-resolution pulse acquisition components to achieve high-precision Accelerometer measurements. The test system supports computer software program control, which can not only realize a single test, but also realize a multi-functionAutomatic test, reducing human participation in the test.The basic structure of the system is shown in Figure 1. It mainly consists of three parts: power supply component, I/F conversion circuit and pulse counting component. The power supply component is responsible for providing power for the I/F conversion circuit and the sensor under test. The power supply switch provides two layers. Control switch,-layer is controlled by software,-layer is controlled by hardware; I/F conversion circuit is used to convert the current signal output by the accelerometer into a pulse signal; the pulse counting component is responsible for sampling the pulse signal output by the I/F conversion circuit Count, and then upload the collected results to the computer via USB cable for display, processing and analysis.

2. electrical/mechanical interface

Test system power supply input: mains AC220V (50Hz), general three-phase socket;

The power supply output of the sensor under test: +15V/0.2A, -15V/0.2A, terminal or connector form;

Data output interface: square USB interface;

The appearance of the chassis adopts the appearance of a 1U industrial computer.

3. Three, the main function

(1) Collect current signals of three accelerometers;

(2) Store test data and export test data;

(3) Calibration function: the external input standard current source can calibrate the scale factor of the system;

(4) Threshold current: ≤5nA, range can be ciustomzed;

(5) The system can performAutomated test configuration functions. Through the software setting process, the accelerometer's repeatability, stability, high and low temperature and other test requirements can be automatically completed without human intervention.

4. Four, product physical map

Close